High Power Density Electrochemical Thermocells for Inexpensively Harvesting Low‐Grade Thermal Energy

The transition from a world that largely depends upon fossil fuels to one that widely utilises sustainable energy requires the development of cheaper and more powerful energy-harvesting technologies. The efficient harvesting of waste heat is a promising strategy to help meet this global need. Waste thermal energy is everywhere, from in our combustion-powered vehicles to in waste streams from chemical and power plants, and little is being harvested as electricity. Research into means for thermal to electrical energy conversion has predominantly focused on solid-state devices that use expensive semiconductors. However, the cost effectiveness of these devices, particularly for harvesting the abundance of “low-grade” (< ca. 150 °C) waste heat sources, is still not sufficient for widespread commercially viable.

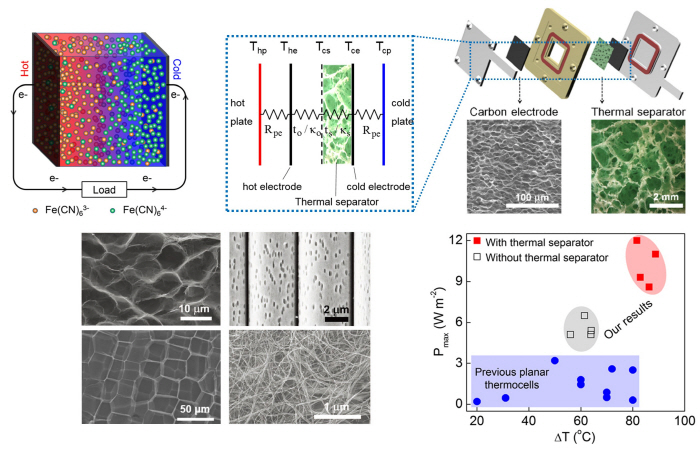

Thermo-electrochemical energy harvesters are alternative devices that can potentially be made at lower cost and used in diverse configurations, such as sheets wrapped around hot pipes. These devices have a hot and a cold electrode, between which is contained an electrolyte containing an ion with two redox states (called the redox couple), which is critically important for enabling continuous operation of the harvester and determining its output voltage. This publication reports significant improvements to the areal power-output of thermocells by making key advances in three areas.

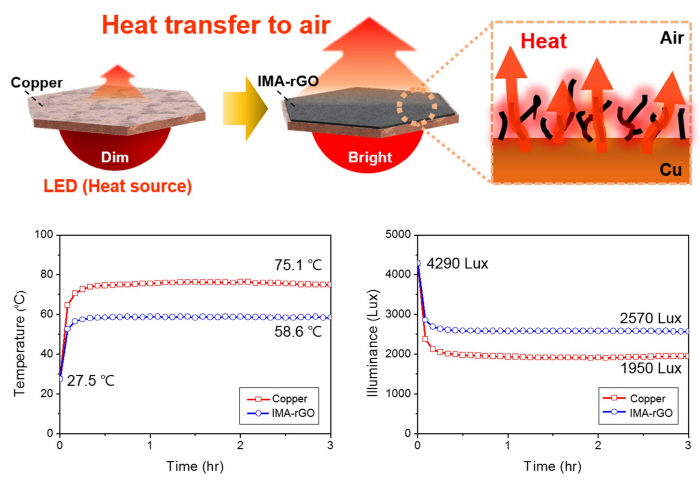

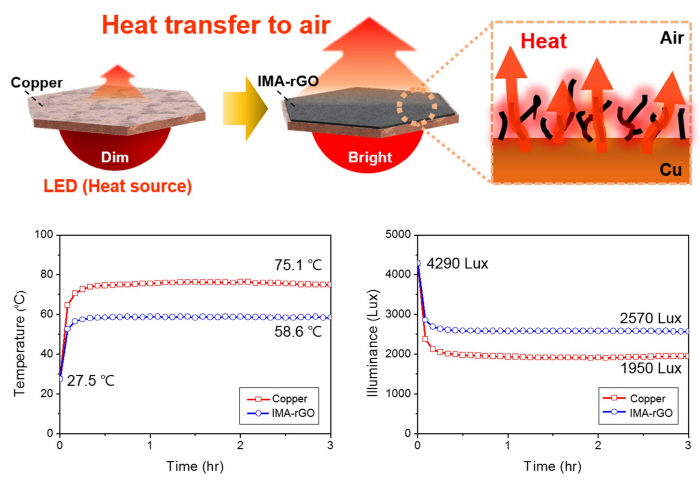

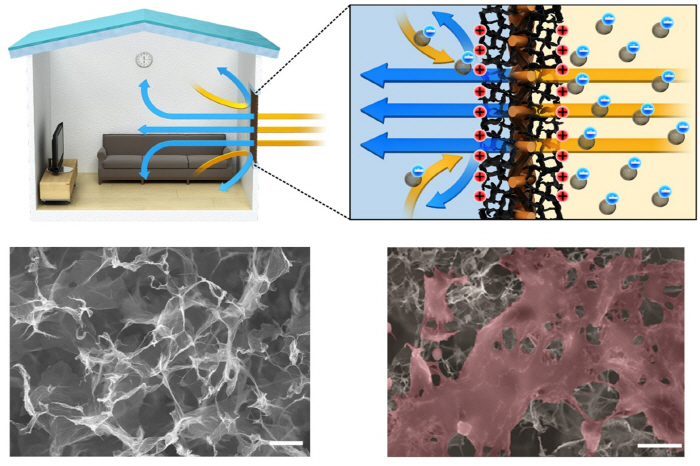

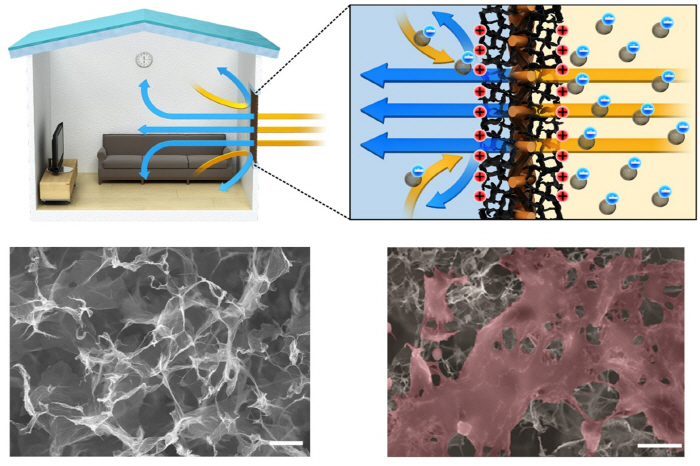

Firstly, in order to appropriately profile temperatures between the hot and cold electrodes and optimize the inter-electrode temperature drop, which are important for maximizing power output, porous thermal separators were developed and appropriately positioned at the cold thermocell electrode. Secondly, the potential cost of the device was significantly reduced by using inexpensive carbon electrodes, instead of platinum, and thermal sheet separators made from cotton fiber or rubber kitchen sponges. These carbon electrodes, made from activated carbon cloth or pyrolized cork, were designed to have very large surface area and a vascular structure, which allows high areal power densities to be achieved. Thirdly, the electrolyte system was improved by realising higher concentrations of the redox couple that is critically important for device operation. This electrolyte is water-based, which decreases cost. Using these advances, demonstrated thermocells produced six-fold higher power than previously reported for planar Pt-free thermocells operating at atmospheric pressure.

Button-cell thermal energy harvesters, which look like an ordinary button cell battery, were made that continuously produce power when heated on one side and cooled on the other side. These button cells, using activated carbon cloth electrodes and a cotton separator, produced 2.6 times higher areal output power that previously reported button-cell harvesters.

An array of 14 interconnected thermocells was constructed that contained both n-type and p-type electrolytes, which is analogous to the array of n-type and p-type semiconductors in commercial thermoelectric harvesters. Connection of four of these arrays together produced a total of 2 volts when harvesting a temperature difference of only 21°C. The application of these series-connected thermocell arrays was demonstrated by charging a commercial capacitor.

To enable thermocells that can harvest thermal energy for hot source temperatures at up to at least 150°C, the above aqueous electrolyte was replaced by a high boiling organic electrolyte and a novel pin array was exploited to increase effective electrode surface area. Using these advances, as well of the thermal separator, an areal electrical power density was obtained that is 2.2 times higher than previously obtained for an organic electrolyte thermal cell.

High Power Density Electrochemical Thermocells for Inexpensively Harvesting Low-Grade Thermal Energy. L. Zhang,† T. Kim,† N. Li, T. J. Kang, J. Chen, J. M. Pringle, M. Zhang, A. H. Kazim, S. Fang, C. Haines, D. Al-Masri, B. A. Cola, J. M. Razal, J. Di, S. Beirne, D. R. MacFarlane, A. Gonzalez-Martin, S. Mathew, Y. H. Kim, G. Wallace, and R. H. Baughman, Adv. Mater. 29, 1605652 (2017). Link

You May Also Like

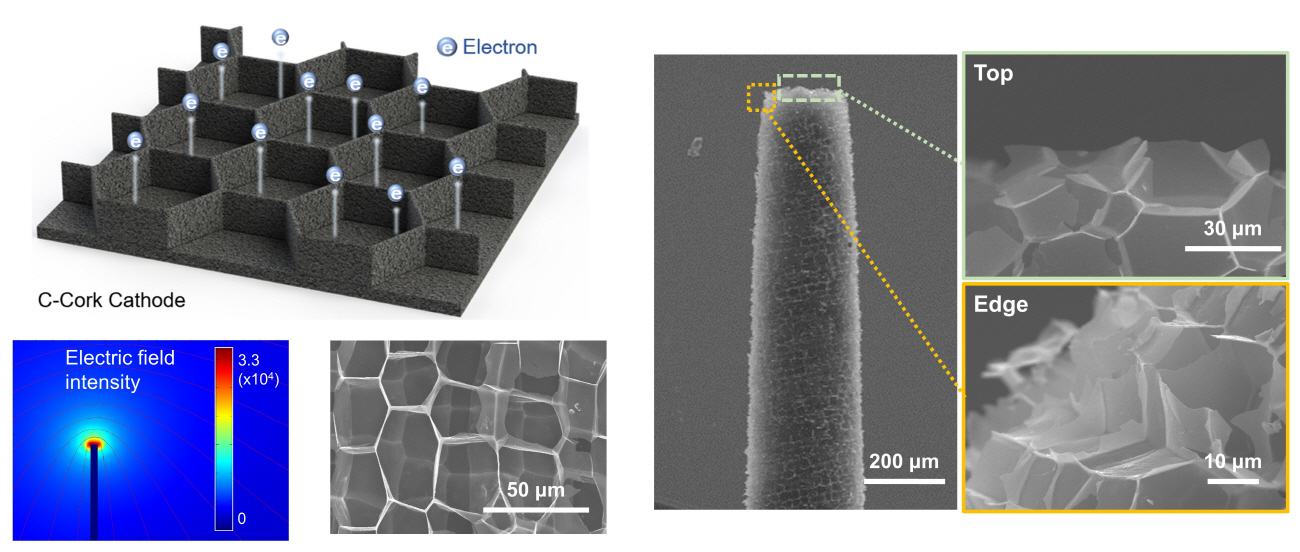

High-Performance Field Emission from a Carbonized Cork

August 5, 2019

An efficient reduced graphene-oxide filter for PM2.5 removal

August 7, 2019